Featured collection

DISCOVER OUR BESTSELLERS

WE'RE LOWERCASE

THOUGHTFULLY DESIGNED, EXPERTLY CRAFTED

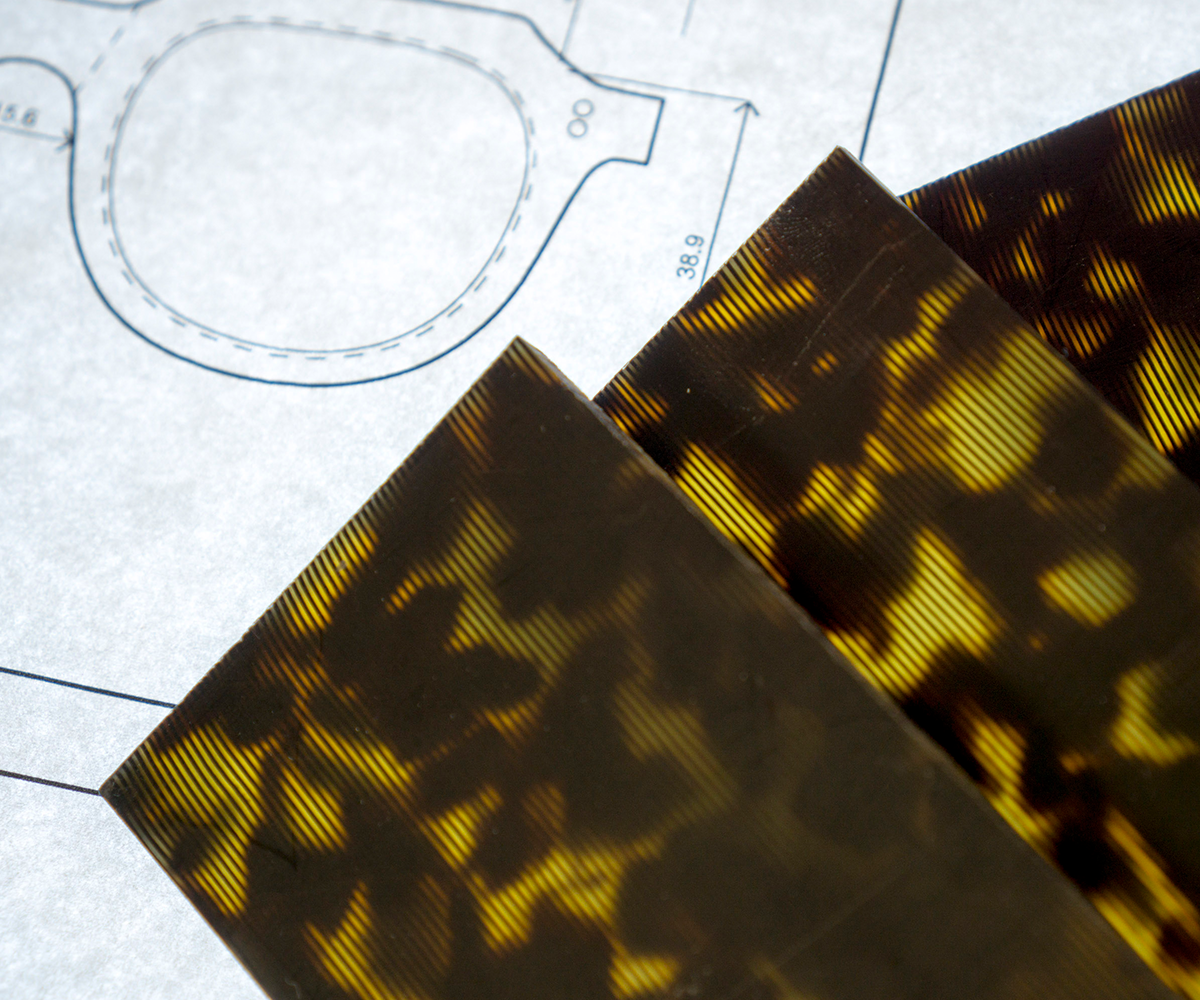

Every pair of Lowercase frames is meticulously handcrafted from start to finish in Brooklyn, NY. Every detail is intentional, every joint and edge impeccably finished. From design to delivery, nothing leaves our hands until it’s on its way to you.

WE'RE LOWERCASE

HANDMADE IN BROOKLYN

We carefully make each and every Lowercase frame by hand in our Brooklyn factory. Our small-batch approach to manufacturing combines new technology with traditional handcrafting techniques. We prioritize craftsmanship above all else, resulting in frames that stand above the rest in quality and design.

WE'RE LOWERCASE

NOT JUST AN EYEWEAR BRAND

Lowercase is a company with a mission: to once again localize the trade of made in USA eyewear, while creating a product that is unparalleled in quality and design. Part of an emerging movement in American manufacturing, we operate at a small scale and prioritize craftsmanship above all else.